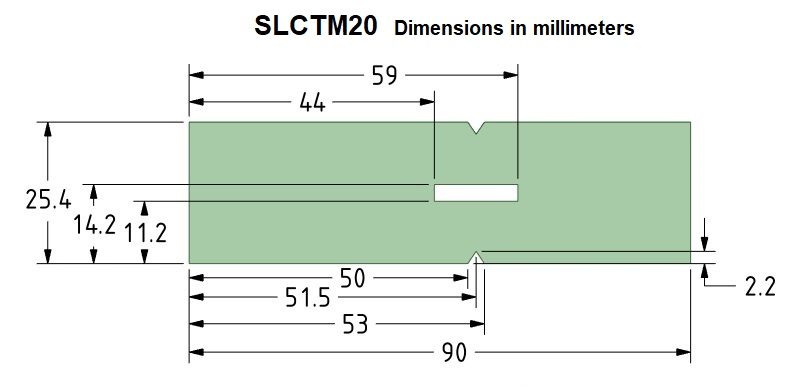

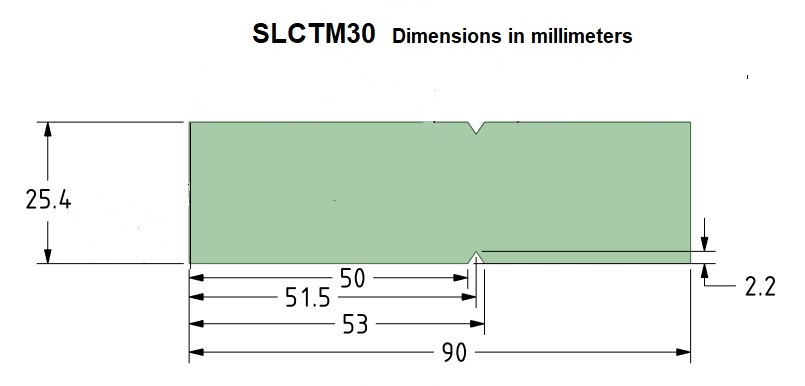

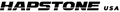

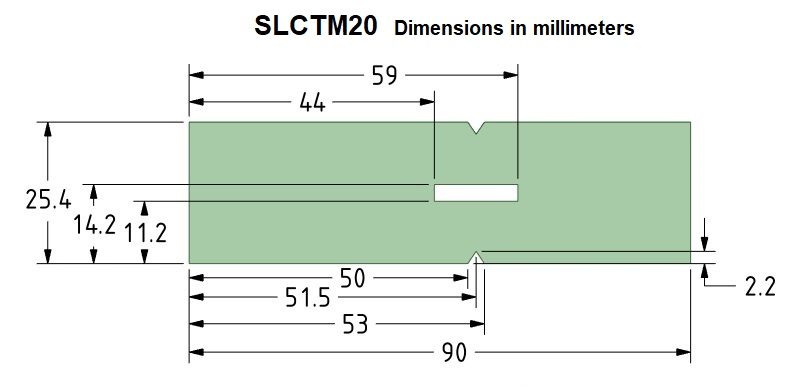

Push cuts (chopping) and slicing cuts are two different technological animals when it comes to measuring edge efficacy but who says "you can't have your cake and eat it too"? EDGE LAB instruments operate in two distinct modes; MAX (Sharpness) and SLC (Slicing). Our EDGE LAB instruments not only perform sharpness tests (push cut), just like our PT50 SERIES units do using the ATF10G test fixture and TM02 test media (ATF10G & TM02 included), but slicing tests as well! Our specially designed slice test fixture (SLCF20 included) works in conjunction with slice test media. Slice test media is only 0.25mm (.010") thick polymer plastic and available in two different configurations; SLCTM20 & 30. Both styles will enable you to compare your results with the results of other sharpeners as well as against edges with established sharpness and slicing characteristics. Either style SLCTM test media may be push cut (an additional way to look at edge sharpness) or sliced with each test, push or slice, yielding dozens of computer logged data points as opposed to our standard sharpness tests which yield just one data point.

The question "Toothy or polished?" is settled quickly and definitively by EDGE LAB. Speculation regarding this question , and a dozen others that have endured for decades in the edge sharpening community, are answered just as quickly. EDGE LAB instruments clearly indicate the effect of blade geometry (even bevel geometry) on the amount of force required during the slice. There’s even more though… you don’t have to use our test media in the SLCF20 slice fixture. You can use paper, card stock, or rubber etc. Virtually any material that is flexible, can be sliced and is no more than 2mm (.080") thick, can be used in place of our slice test medias. Slicing tests may be conducted manually with the included SLCF20 test fixture or with the aid of one of our Slice accessories. Sharpness tests are conducted with the included ATF10G test media fixture and KFL10R knife fulcrum or with our iDCB10 test clip base and DTC100 test clips (DCB10 and test clips included with the E ∙ LAB A ) .

It's not just about EDGE LAB’s ability to determine sharpness or slice efficacy though. EDGE LAB allows you to combine these independent pieces of information for an extremely accurate appraisal of how any edge will perform in the kitchen or on the manufacturing floor.

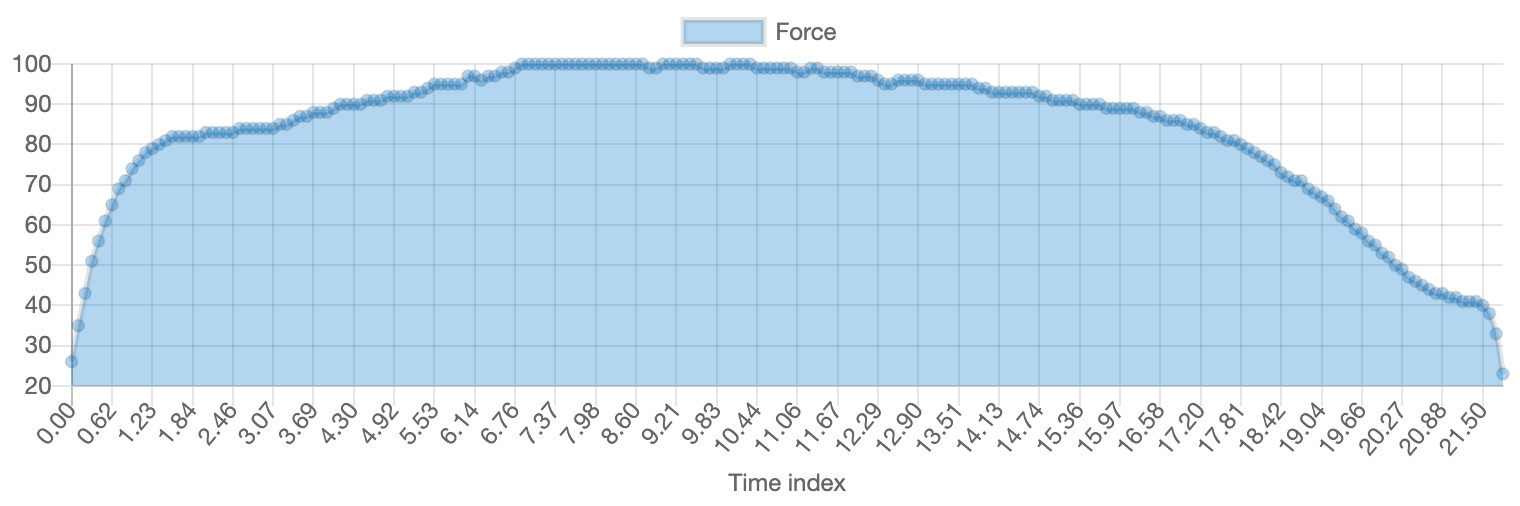

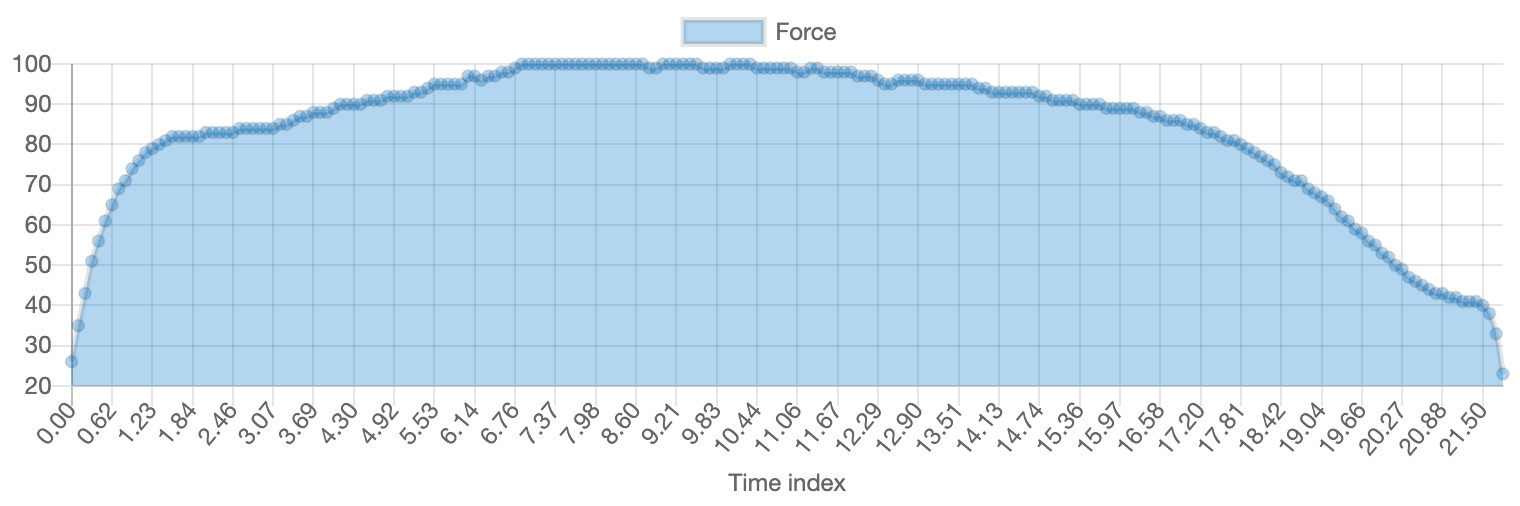

Our Windows based Standard PC User Interface (UI) is super quick and easy to install and operate and is included with your instrument on a USB thumb drive. Our Standard UI allows users to set test parameters and calculates and displays average force readings for either push or slice cuts (yes, you can conduct push cut tests while using slice test media). What's the difference in force required for push versus slicing cuts? The difference may surprise you. Your EDGE LAB instrument is connected to your PC USB port via cable. Our Standard User Interface also generates CSV format data files that can be saved and/or directly exported to Excel for advanced analysis or graphing. Our Pro UI does everything that Standard does plus automatically generates real time data trimmable graphs like this:

The EDGE LAB line is fully supported by a complete line of accessories. Our CNC10 allows very controlled slice tests where the X and Y axis is always in constant ratio throughout the slice test. Our SLT10 Slice Tray accessory allows you to use anything from a tomato to a chunk of rubber for real world testing. All EDGE LAB instruments are fully compatible with all PT50 Series sharpness testing accessories and test media forms with the exception of the KF10R knife fulcrum. All EDGE LAB instruments use the included KFL10R knife fulcrum.

Which edge style is most slice efficient - serrated or scalloped, poished or toothy? Does it make a difference if the slice motion is slow or fast, and how does this all relate to applied force? We know that blade geometry makes a difference but exactly how much? All these questions plus a dozen more can be answered by an EDGE LAB instrument quickly, economically and assuredly because the engineering theory that guided the development of EDGE LAB is practically infallible. Now it's time to decide which EDGE LAB model is best for your application...